Jump to: Information | Photos | Customers | Models | Compare models | Customizations | Warranty | Specifications | Videos

Prevent Trailer Creep

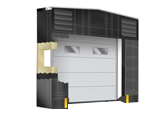

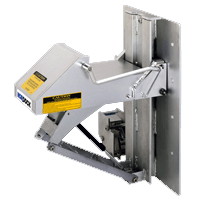

The ATL trailer restraint ensures the safety of your workers by preventing vehicles from moving forward during loading or unloading. With mounting forces exceeding 100,000 pounds, our trailer restraints are capable of holding the heaviest trucks while the locking hook secures virtually all rear impact guards in excess of 32,000 pounds of restraining force to eliminate trailer pinch.

✓ The strongest hold: With mounting forces exceeding 100,000 pounds, our trailer restraints are capable of holding the heaviest trucks while the locking hook secures virtually all rear impact guards in excess of 32,000 pounds of restraining force to eliminate trailer pinch.

✓ One size fits all: Able to lock a variety of trucks with a vertical operating range from 9″ to 30″.

✓ Prevent serious workplace injury/accidents: Ensure the safety of your workers and prevent the truck from moving forward during loading.

✓ Flexible: Hydra-Float barrier automatically adjusts to track movement during loading.

✓ Durable: All components are zinc plated for superior durability and weatherproofing.

Photos

Videos

Pit-Hook OperationWatch how the Nordock Pit-Hook operates to lock a trailer bar. |

ATL Trailer RestraintsPrevent accidental trailer departure with ATL automatic trailer restraints from Nordock, which provides continuous upward force once docked. |

Models

|

Automatic: ATL seriesThe Truck-Lock automatic series of trailer restraints improve safety with strength, convenience and reliability.Models: ATL-400, ATL-450, ATL-500, ATL-900 |

|

Manual: MTL seriesThese Truck-Lock trailer restraints are affordable, manually-operated units designed to lock trailers with a large barrier.Models: MTL-100, MTL-200, MTL-230, MTL-250, MTL-300 |

|

Pit hook: Pit-Hook PH3000The Pit-Hook model is a premium automatic hydraulic-powered unit with a restraining hook that is stored at the back of the building face, clear of incoming trucks within a pit cavity below the dock leveler, away from weather and debris. |

Model comparison chart

| ATL-400 | ATL-450 | ATL-500 | ATL-900 | |

| Vertical operating range | ||||

| Mounting force | ||||

| Restraining force | ||||

| Enclosed working parts | ||||

| Rotating hook | ||||

| Battery-back-up | ||||

| MTL-100 | MTL-200 | MTL-230 | MTL-250 | MTL-300 | |

| Vertical operating range | |||||

| Mounting force | |||||

| Restraining force | |||||

| Enclosed working parts | Yes | Yes | Yes, NEMA 12 rated | Yes, NEMA 12 rated | Yes, NEMA 12 rated |

| Rotating hook | |||||

| Battery-back-up | |||||

Customizations

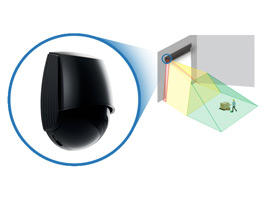

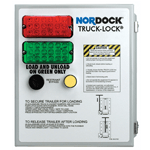

Complete communication system for all models |

||

|

|

|

| Flashing LED signal lights for inside/outside usage. | Wall-mounted sign with reverse writing for easy driver readability. | Control panel with simple push-button operation. |

Additional options |

||

| • Cantilever extension mounting bracket. • Cast-in wall mounting plate. • AR-10K/Pit-Hook: Keyed override switch. • Pit-Hook: Dock leveler stored interlock switch. |

||

Warranty

- 1 year: Parts

- 5 years: Structural

Specifications

| Components | Zinc plated for superior durability |

| Design | Non-impact design with low profile (9" above grade) |

| Guide tracks | Self-cleaning |

| Components | Steel hook constructed from 50,000 psi yield material |

| Design | Non-impact design with low profile (9" above grade) |

| Horizontal extension | 14" |

| Mount | Under dock pit |