Energy rebates available –Discover your energy rebate, annual savings and ROI »

Jump to: Information | Photos | Videos | Customers | Models | Compare models | Customizations | Warranty | Specifications

The HVLS Fan – The Power of 34 Fans in One

One HVLS ceiling fan can do the work of 34 small industrial fans. Save on energy costs on as the single HVLS fan has low operational cost of $0.25-$1.50/day, compared to running 34 fans. Also free up floor and table space, by replacing multiple pedestals fans with a single HVLS fan.

Improve Air Circulation

Reduce Health Risks

Provide a Cooling Effect

Manage Condensation

Reduce Heating Costs

No Need for Pedestal Fans

- Lower your energy bills: Save up to 25% on heating costs and up to 30% on cooling costs.

- Unrivalled warranty: Stay at ease with warranties for up to 15 years.

- Energy rebates: Be eligible for energy rebates in select areas of Ontario and Alberta.

- Low operational cost: Move the most amount of air for the low operational cost of $0.25-$1.50/day.

- Maintenance-free: All MacroAir HVLS Fans only have two moving parts. A gearless, direct-drive motor drives the fan without using oil. No oil = no leaks!

- Increase worker productivity: These HVLS Fans use evaporative cooling to make workers feel up to 8°F cooler, reducing the number of heat stress breaks.

- Improve worker and product safety: Prevent condensation build-up on floors and products.

We have over 10 years of expertise in designing placement setups and installing HVLS fans. We have installed more HVLS fans than any other company in Canada.

Information

What is HVLS and Why is its Technology Revolutionary?

MacroAir HVLS ceiling fans move a High Volume of air at a Low Speed (HVLS). Longer blades create a wider column of air that travels farther than conventional fans, while the low speed provides gentle air movement rather than disruptive wind. In addition, the amount of power needed to drive the MacroAir HVLS Fan is reduced due to its low velocity. MacroAir HVLS Fans result in complete air circulation with nearly silent operation. These fans operate at a minimal cost of approximately $0.25-1.50/day, depending on the model.

- Immediately improve working conditions by making employees feel warmer in the winter and up to 8°F cooler in the summer.

- Improve air quality and reduce the health risks by circulating fresh air through the facility to prevent inadequate airflow and poor ventilation.

- Reduce energy bills by 1% per foot of ceiling height.

- Save energy in the summer by raising your thermostat setpoint (save 6% per degree raised).

- Equalize temperatures from floor to ceiling and front to back.

- Speed up processing times for manufacturing, printers, disaster recovery, etc.

- Increase safety by reducing condensation and moisture build-up.

- Warm-up large areas 5x faster through even heat distribution.

- Improve worker productivity by regulating air temperatures to reduce heat stress breaks.

- Can work with your existing HVAC system by helping circulate air to the ceiling to make it easier for your HVAC system to cycle the air.

Comparing a Direct Drive Motor to a Traditional Motor

MacroAir Direct Drive Motor:

|

|

Traditional Motor:

|

Prevent Health Risks and Improve Air Quality

HVLS fans circulate fresh air throughout your facility to improve air quality and reduce the health risks from inadequate airflow and poor ventilation. Poor airflow causes stale warm air, which is a breeding ground for bacteria and other pollutants. As a result, these pollutants cause breathing issues, illnesses and other health issues. Keep employees healthy maintaining a fresh air supply and airflow.

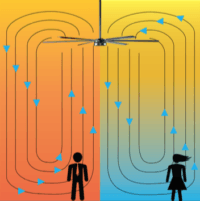

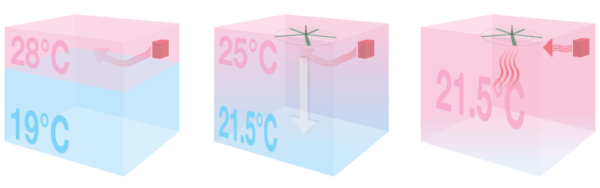

HVLS Fans Can Be Used in Both Winter and Summer

Use your HVLS fan all year to save up to 25% on heating costs and up to 30% on cooling costs! Create a breeze with an evaporative cooling effect in the summer to make people feel up to 8°F cooler. On the other hand, in the winter months, your HVLS fan will push down the warm air from the ceiling to keep everyone warm in the winter months.

Winter usage (left): Slow-moving air column carries warm air from the ceiling down to floor level.

Summer usage (right): Large air column delivers a cooling breeze across the entire body.

Watch How Air Moves in Your Facility

Visualize the air movement in your facility with MacroAir’s exclusive AirViz visualization software. AirViz is specifically designed to help strategically place MacroAir HVLS Fans in key areas to move the maximum amount of air in any given space despite obstructions such as walls or tall racks. Book your free AirViz virtualization with us.

HVLS Fans are Used in Every Industry

Commercial

- Retail

- Transportation stations

- Laundromats

- Farming

- Banquet halls

- Airports

- Airplane hangars

Industrial

- Manufacturing facilities

- Industrial shops

- Warehouses

Automotive

- Drive-through services

- Wash bays

- Parts areas

- Lube and mechanic bays

- Shop doors and showrooms

Food

- Restaurants

- Outdoor patios and gazebos

- Coffee shops

- Breweries

- Food courts

Education

- Hallways

- Classrooms and lecture halls

- Gymnasiums

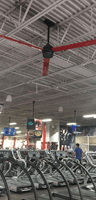

Fitness

- Fitness centres

- Sports clubs

- Sports arenas and stadiums

Photos

Videos

Smart ReinventedFind out the inner workings of the on-board AirBrain microprocessor. |

Quiet ReinventedMacroAir HVLS Fans run silently in the background. |

Power ReinventedGet insight into the breakthrough direct drive motor technology for HVLS Fans. |

Air ReinventedWith its NASA-engineered wing design, MacroAir HVLS Fans move the most amount of air in any given space. |

Cooling AnimationHVLS fans are able to make workers feel up to 8°F cooler in the summer. |

The Power of 34 FansReplace 34 small industrial fans with one HVLS ceiling fan. |

Customize the Color of Your FansCustom powder-coating is available for all fan blades, mounts and drop lengths in a variety colours. |

Customers That Love This Product

After the installation of a few MacroAir HVLS Fans, we’ve seen a positive impact in equalizing temperatures throughout our facility which resulted in significant gas savings.

This past week with it being so cold we have noticed that the air barriers have stopped the cold from getting in and the fan keeping the warm air moving, allowed us to work in t-shirts because we are so comfortable.

Working with Northern Dock Systems for installation of our HVLS [fan] has been a great experience for Corvex! From quotation to installation, Adam and his team provided excellent customer service and support.

Click a logo below to view the success story

Models

|

AVDXThis fan boasts a bullet-proof, industrial-grade, direct drive motor/controller platform more powerful and far superior than any fan before. The AVDX is a true workhorse that can endure the harshest industrial environments without breaking a sweat, while the silent operation and sleek design features make it an excellent choice for even the chicest of spaces. With a breakthrough gearless direct drive motor design, the AVDX fan delivers massive airflow for extra-large spaces. |

|

AirVolutionThe AirVolution uses a proven industrial gearbox driven power unit in combination with integrated network technology. Combine with one of our multi-fan network controllers, AirEffect temperature control, or AirLynk for Building Management Systems for advanced control. With a premium industrial gear motor and advanced control platforms, you get more than fan, you get one of the most versatile cooling solutions available on the market with FDA food-grade stainless steel and explosion proof motor options. |

|

AirLegacyThe ultimate utility fan, the MacroAirAirLegacy industrial fan uses tried and true technology which is proven to last over time. The AirLegacy uses a reliable gearbox-driven power unit to provide huge airflow at a great value. With basic features, accessories and analog controller, the AirLegacy industrial fan will meet any budget while performing better than any fan in its class. It is available in explosion proof motor options. |

|

AirVolution-D3 (AVD3)Simplicity is key with the AVD3 industrial ceiling fan. Its three-blade design reduces weight, friction, and raw materials, which in turn minimizes the strain on the building, energy consumption, and your budget. |

|

AirVolution-D 370 (AVD370)Ideal for ceilings as low as 12 feet, the AirVolution-D 370 is the perfect solution for cooling your smaller spaces. AVD370’s sleek design makes this the perfect fan for restaurants, houses and patios. |

Model Comparison Chart

| AVDX | AirVolution* | AirLegacy* | AVD3 | AVD370 | |

| Diameter | 8'-24' | 8'-24' | 8'-24' | 10'-24' | 6'-12' |

| Number of blades | 6 | 6 | 6 | 3 | 6 |

| Spacing between fans | 50-110 ft apart | 50-110 ft apart | 50-110 ft apart | 55-95 ft apart | 28-48 ft apart |

| Weight | 156-260 lbs | 171-270 lbs | 171-270 lbs | 129-162 lbs | 52-74 lbs |

| Motor | Gearless Direct Drive | Industrial Gearbox | Industrial Gearbox | Gearless Direct Drive | Gearless Direct Drive |

| Horsepower | 1.25 or 2.3 hp | 1.0, 1.5 or 2.0 hp | 1.0, 1.5 or 2.0 hp | 1.05 hp | 0.7 hp |

| Control options | Digital touchpad | Digital touchpad | Analog remote | Digital touchpad | Digital touchpad |

| AirLynk Automation | Yes | Yes | No | Yes | Yes |

*Available in FDA/Stainless and Explosion Proof Motor Options: These versions come with an analog remote, 1.0 hp motor and gearbox. Only available for 8ft-18ft HVLS fans.

Customizations

Customize the Color of Your FansCustom powder-coating is available for all fan blades, mounts and drop lengths in a variety colours. |

|

|

Controller 4 and Controller 30Seamlessly control up to 4 or 30 fans at one centralized location with a fully integrated LCD touchscreen panel. Fans can be run at speeds and directions independently of one another or synchronize. In addition, attach a temperature sensor to start and stop gans based on your desired temperature threshold to take the guesswork out of providing maximum comfort. |

|

AirLynk BMS IntegrationYou can integrate your HVLS fans into your existing Building Management System (BMS) to control and automate all the fans in your facility. No need to add a new control panel, just add your HVLS fans to your BMS console with AirLynk and control everything from one station. |

Warranty

Up to

15 years

Mechanical

Up to

10 years

Electrical

1 year

Labour

AVDX

- 15-year mechanical warranty

- 10-year electrical warranty*

- 1-year labour warranty

AirVolution

- 15-year mechanical warranty

- 7-year electrical warranty*

- 1-year labour warranty

AVD3 and AVD370

- 10-year mechanical warranty

- 5-year electrical warranty*

- 1-year labour warranty

AirLegacy, FDA/ Stainless and Explosion Proof Motor Models

- 15-year mechanical warranty

- 5-year electrical warranty*

- 1-year labour warranty

*Optional Extended Electrical Warranty available.