Project Overview

Curtiss-Wright Nuclear Canada in Newmarket scheduled a preventive maintenance visit to service their overhead doors and dock leveler and to catch any deficiencies with us. Our preventive maintenance technicians inspected, serviced and repaired:

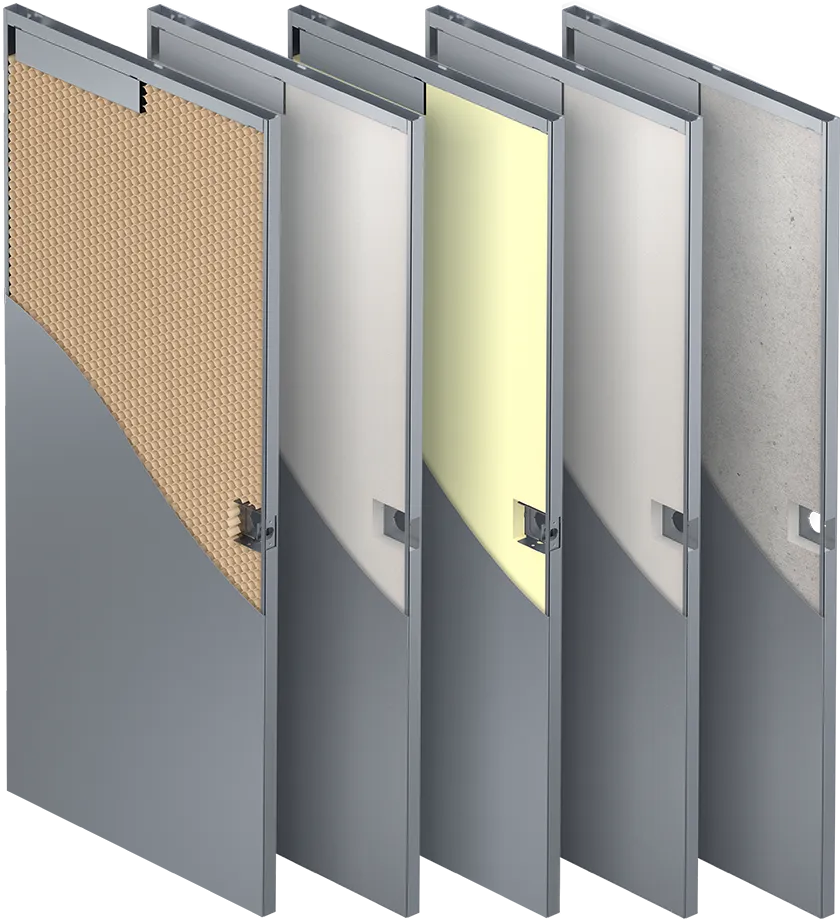

- Manual overhead dock door

- Mechanical dock leveler

- Manual overhead drive-in door

Overhead Door Preventive Maintenance Inspection

During an overhead door preventive maintenance inspection, our technicians will make note of the condition of each part on the door whether it’s in good condition, worn, needs replacement or was replaced.

In the course of manual overhead door preventive inspections, our technicians will:

- Inspect and secure lower jambs and door track, straighten if required

- Inspect door sections for any dents or damage.

- Inspect and lubricate rollers and hinges.

- Inspect and lubricate door springs.

- Inspect the bottom bracket for damage.

- Inspect and adjust the slide lock.

- Inspect and secure the lift handle and step plate

- Inspect the pull rope or chain hoist for damage.

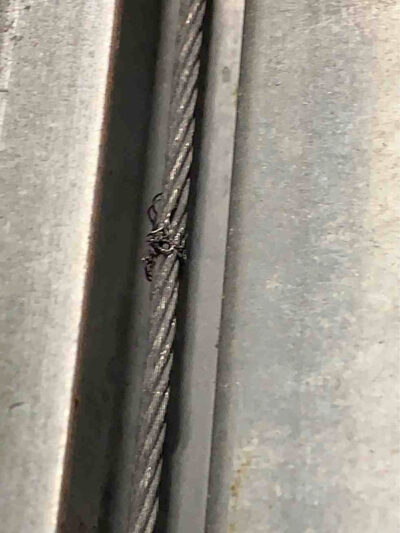

- Inspect cables to make sure they are not frayed or fraying, which could be a safety risk of the cable snapping soon.

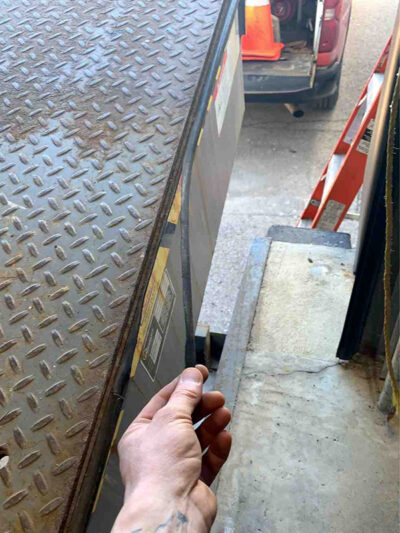

- Inspect the side, top and bottom weather seals to make sure they haven’t been torn off or have any gaps, which would prevent them from properly sealing.

- Clean and inspect the door windows for any cracks or gaps.

Throughout the preventive inspection at Curtiss-Wright, we discovered a couple of issues that were repaired at a later date after they approved all the repairs.

Dock Leveler Preventive Maintenance Inspection

During preventive maintenance inspections on mechanical dock levelers, our technicians will:

- Check full operating cycle to make sure the mechanical dock running smoothly and efficiently.

- Inspect condition of the rear curb angle and welds to dock angle for any breaks.

- Inspect for any torn or missing side weather seal for the dock.

- Inspect deck for any dishing or signs of structural wear, which is a sign of potential dock failure in the future.

- Inspect rear deck hinge for any cracks, breaks or warping.

- Clean of debris, lubricate and inspect front lip hinge.

- Inspect factory maintenance strut to make sure it can safely be used to inspect under the dock.

- Clean pit of debris.

- Inspect all structural components and shims for broken welds.

- Inspect dock lip, crown and shims for damage.

- Inspect dock bumper condition that they are in the correct position and projection along with not being worn down to make sure they are protecting the dock from impacts from trucks.

- Inspect dock seal and/or shelter for any wear or gaps.

- Inspect toe guards to make sure they are present and undamaged to follow provincial safety guidelines.

- Lubricate rear hinges and all pivot points for a smoother operation and to prevent rust.

- Inspect pull chain for damage.

- Inspect lifting springs and adjust tension, as required.

- Inspect, lubricate and adjust hold down, as required.

In addition to the damaged weather seal, the mechanical dock at Curtiss-Wright in Newmarket was missing toe guards.

Our technicians made sure to do all the necessary maintenance and ordered new toe guards to get them back into compliance with safety regulations.