A Summary of the Issues

Pepsi’s bottling facility in London, Ontario was looking to improve safety and efficiency for their four dock positions since their existing dock levelers were in need of replacement. Regular flow of liftgate trailers often created an unsafe condition for employees in and around the loading dock area since there was not an adequate amount of lip purchase when the existing dock levelers were in use. End-loading was also a regular challenge, as forklift operators struggled to maximize all available space in the trailer when loading. Moreover, Pepsi’s existing dock levelers were only 6’ wide, which was quite narrow for the high amount of traffic at this location.The Solution and Results

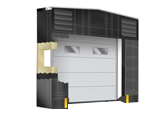

Northern Dock Systems provided turnkey new equipment installation and pit construction solutions to Pepsi. Highlights of Pepsi’s complete solution include:- A Telescoping-Lip dock leveler (TLH) which stores horizontally for fast operation, extending its lip straight into the trailer with only a slight raise of the deck, reducing loading cycle times and improving climate control. The TLH provides infinite end load access with precise lip control, safely bridging the gap between deck and trailer bed for forklift access and avoiding potential damage to cargo and/or forklift.

- Custom 24” lip extension for precision control and positioning, full end-load access and reduced load cycle times.

- Steel faced dock bumpers to protect the building from repeated trailer impact.

- An improved footprint from 6’x8’ to 7’x8’.

- Flush storing to increase floor space for cross-traffic operation, which was ideal for this facility.

- Extended service range (12” above and below service).

- Reliability and worry-free operation with a 10-year structural and 20-year rear hinge warranty.

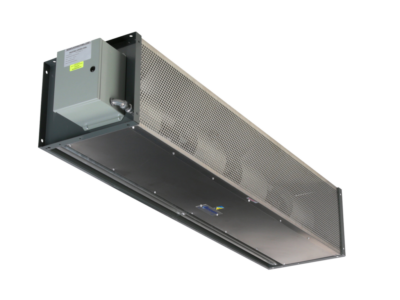

- Side brush weather seal kit and bumper to bumper hinged front seal provided exceptional climate control.

Additional Turnkey Solutions Provided

- Removal and disposal of existing dock levelers.

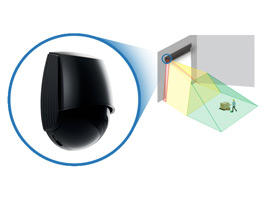

- Installation of dock leveler, electrical connection and interlock with existing GMR restraint system.

- New pit construction with concrete (installation of pour-in pan only), including construction of a new pit at 7’ wide from pre-existing 6’.